PCBA water based cleaning process

① Cleaning object:

Types, sources and hazards of pollutants:

The mechanism of pollutant attachment is as follows

From the microscopic point of view, the combination or adhesion between substances mainly depends on the combination of atoms and atoms or molecules and molecules. The former is called "chemical bond" binding, and the latter is called "physical bond" binding. Sometimes these two kinds of bond energy combination coexist with each other. In addition, the mechanical anchoring effect is formed due to the surface roughness, which promotes the adhesion of pollutants.

Cleaning process mechanism:

The mechanism of cleaning is to destroy the chemical bond or physical bond between the pollutant and the substrate. The purpose of separating pollutants from substrate is mainly achieved by wetting, dissolving, emulsifying, saponification and chelating of cleaning agent.

One of the related explanations of cleaning mechanism:

Cleaning mechanism (2)

Cleaning mechanism (3)

Cleaning mechanism (4)

Cleaning mechanism 5

② Application of cleaning materials:

Comparison of water-based cleaning agent and solvent cleaning agent:

Cleaning method corresponding to solvent cleaner:

Corresponding cleaning method of water-based cleaning agent:

③ Conventional process flow of using water-based cleaning agent:

Related factors affecting the cleaning (PCBA cleaning) process window:

PCBA cleaning process and quality monitoring

A. Cleaning section: the cleaning fluid is determined according to the corresponding indexes through the following methods, and the cleaning effect is measured, and whether the cleaning fluid needs to be replaced is determined.

PCBA cleaning process and quality control (2)

B. Rinsing section: the concentration of water-based cleaning agent in the discharged rinsing water can be monitored by the following methods.

Cleaning process and quality control of PCBA

C. Quality standard after cleaning: we can measure the cleanliness of cleaning through these two indicators: ion test and Sir test for PCBA board.

PCBA cleaning process and quality control

D. Cleanliness test standard

1. Relevant standards:

Ipc-j-std-001e requirements for welded electrical and electronic components

Mil-std-2000a / mia-p-28809 US military standard

Cleanliness test and classification of sj20896 printed circuit board assembly after assembly and welding

Welding of electronic components in hb7262 Avionics

Ipc-a-610 (acceptability of electronic components)

IPC ch-65b CN (PCB and assembly cleaning Guide)

Cleanliness standard of China Electronics Society

2. According to the relevant provisions of the military standard sj20896 of electronic industry, the cleanliness of electronic products is divided into three grades according to the reliability and working performance requirements of electronic products

3. In practice, it is almost impossible to eradicate pollution. A compromise is to determine the acceptable and unacceptable levels of contamination on circuit boards. According to the ipc-j-std-001 standard, the flux residue is less than 40ug / cm2, the ion pollutant content is less than 1.5 (NaCl) UG / cm2, and the extraction resistivity is more than 2 × 106 Ω· cm

Please note that with the miniaturization of PCBA, it is almost certain that this content is too high. At present, the commonly used ion pollutants require about ≤ 0.2 (NaCl) UG / cm2

E. Inspection method of cleanliness

1. Visual inspection

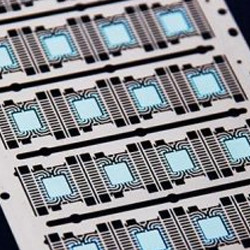

The components were observed by magnifying glass or optical microscope, and the cleaning quality was evalsuated by observing whether there were flux solid residue, tin slag, tin bead, unfixed metal particles and other pollutants. The general inspection guide for electronic components after assembly is provided in ipc-610-a.

The visual inspection criteria listed in ipc-a-610 range from 1 × (naked eye) to 10 × as a judgment method, as shown in the table below. This method is not suitable for the simple detection of residual contamination in the bottom of components.

Ipc-a-610 table

Note 1: visual inspection may require the use of amplification devices, such as in the presence of fine pitch devices or high-density components, magnification is required to check whether contaminants affect the shape, assembly or function of the product

Note 2: if the amplification device is used, the magnification shall not exceed 4 ×

2. Solvent extraction test method

Solvent extraction liquid test method is called the average test of ion pollutant content. The test generally adopts IPC method (ipc-tm-610.2.3.25). It is to immerse the cleaned components into the test solution of ionic degree pollution tester, dissolve the ionic residue in the solvent, collect the solvent carefully and measure its resistivity.

3. Ion contaminant equivalent test method (dynamic method)

Refer to section 6.3 of sj20869-2003

4. Surface insulation resistance test method (SIR)

This test method is to measure the surface insulation resistance between conductors on the module. The surface insulation resistance measurement can indicate the leakage of electricity due to pollution under various conditions of temperature, humidity, voltage and time. Its advantages are direct measurement and quantitative measurement. The general SIR measurement conditions are as follows: the ambient temperature is 85 ℃, the humidity is 85% RH and the measurement bias voltage is 100V, and the test time is 170 hours.

5. Residual flux detection

Refer to section 6.4 of sj20869-2003

Replacement method of water-based cleaning agent:

1. On line through spray cleaning machine

Water based PCBA cleaning related application equipment 2:

2. Automatic cleaning machine

Water based PCBA cleaning related application equipment 3:

3. Off line cleaner

Water based PCBA cleaning equipment (4)

4. Oven

⑥ Example process:

1. Application equipment: ultrasonic cleaning machine

2. Process flow:

3. Related process description:

4. Cleaning effect

Summary:

1. Water based cleaning agent has super dissolving and cleaning power, which is incomparable effect of traditional solvent cleaning agent. It can be applied to all types of flux residue cleaning, and greatly improves the safety level and environmental material level.

2. It fully meets the requirements of RoHS, reach, sony00259, HF and other environmental protection regulations.

3. Wide process window, not affected by the cleaning method and equipment, fully meet the cleaning requirements of various manufacturers.

4. Thoroughly remove the hidden danger of fire.

5. Improve the affinity between the environment and people (no pollution to the environment, no harm to the human body).

6. Water based cleaning agent is non-volatile, can be recycled, greatly reduce production costs, improve market competitiveness.

To sum up, the water-based cleaning agent series products can not only provide you with effective, safe and cleaning agent, but also help you find the cleaning process solutions, comprehensively reduce the operation cost for you and improve the market competitiveness! Help you to realize the comprehensive upgrade of equipment, technology and materials!

中文(簡(jiǎn)體)

中文(簡(jiǎn)體)